25 years of experience in machine cutting

Recently added

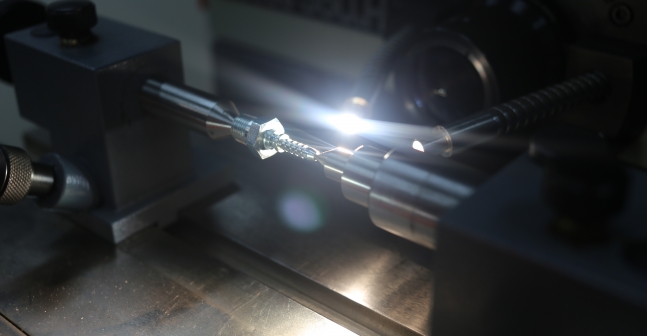

CNC turning and milling

Check our production capabilities. We produce fixtures designed by our clients or we design them tailored to our customers’ needs.

Hitachi Seiki VS60

2015-06-01Hitachi Seiki VS60 - 4-axial CNC milling machine (produced in 2001)

Following many modernisations and repairs, production was commenced on Hitachi Seiki VS60 milling machine controlled by Seicos ∑18. The machine is equipped with a unit containing 90 holders, thus it is possible to set it up for a variety of production orders and to set off machining without the need to prepare tools, which are ready to be used. Therefore, the process of setting off production is significantly shorter, and it allows us to deal promptly with customers’ requisitions and efficiently process discrete productions.

Screw propellers underwent regeneration, which combined with large mass of the corpus gives very high stiffness and precision of machining. In addition, drivers of X and Y axis were repaired and elements of hydraulics replaced. The machine has a hydraulic mist separator, which makes the operator’s work more comfortable.

The machine is also equipped with a network interface adapter to allow the operator to copy a proper machining programme directly from the server. It does not require confirmation of receipt, as it is in the case of communication through RS-232.

RENISHAW machine tool probes and BLUM laser tool setters guarantee exceptionally precise machining and significantly decrease the production set off time. BLUM measuring systems allow control of tool between particular operations, which gives additional protection against unwanted over sizing resulting from tool tear and wear or damage.