25 years of experience in machine cutting

CNC machining

CNC turning and milling

Check our production capabilities. We produce fixtures designed by our clients or we design them tailored to our customers’ needs.

Technology and quality assurance

For production processes involving machine cutting, we use tools from the best manufacturers in the world and we monitor their quality on an ongoing basis. We also manufacture tools for our internal purposes from HSS steel for fixtures which require a specific shape or they cannot be produced using standard tools.

We control our tools using Zoller Smile 400 machine. It is a top quality machine for measuring tools, control and assessment of cutting edge wear, building a base of tools and sending measurement results directly to the machine tool.

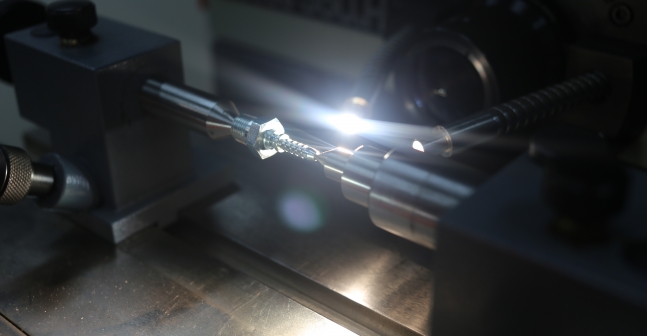

We measure turning elements and threads using MICROTECNICA Helios 350h projector. In addition to standard measurement by transmitted light, the machine may function as a microscope and take measurements using reflected light of the enlarged surface.

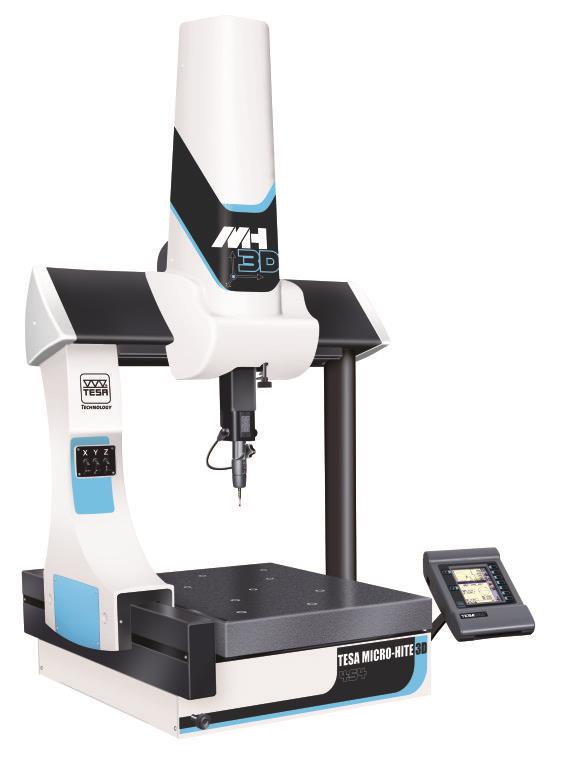

More complex fixtures and automated (pallet) measurement is processed on the coordinate measuring machine TESA Micro-Hite 3D 454. This machine allows high accuracy of measurements with precision up to 0.004mm, and fully automated operation records the results in our internal server, enabling technicians and operators to monitor dimensions in real time.

Operators of machine tools also use high gauge TESA Hite 400. This apparently simple machine offers a wide spectrum of measuring options, allowing 2D measurement when operated efficiently.